Research

Structural Batteries

The high combustibility of Li-ion’s organic electrolyte requires EV designers to thoroughly protect their Li-ion battery packs from impact and other external forces, as well as monitor the battery health to prevent overcharging, over-discharging, thermal runaway, and disproportional voltages of cells in series. While each of these subsystems is important and necessary, they are currently unifunctional and independent. In the worst case, these supporting subsystems can be as much as 42% of the battery pack mass, leaving only 58% of the mass for storing energy. By integrating three subsystems – battery, structure, health monitoring and control – into one multifunctional system, the overall efficiency of the battery system is enhanced by keeping total energy constant while decreasing system-level weight.

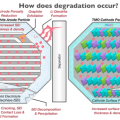

Battery Health Degradation Modeling

One of the most significant issues plaguing Li-ion battery use in EVs is the unpredictability of the capacity degradation of each cell. Even nominally identical batteries from the same manufacturing line can have drastically different cycle lives due to the variety of possible degradation mechanisms at the atomic level. Further complicating this problem is the fact that it is difficult to distinguish the performance of individual batteries at the pack level once they are all strung together in series. Auto manufacturers resolve this issue by limiting the usable capacity of the battery to minimize the rate of degradation at the cost of vehicle range. By understanding, modeling, and predicting the degradation behavior of individual cells in the battery pack, the limitation on the pack capacity can be reduced to increase the range of EVs.

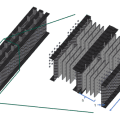

Pack Design Optimization

While material scientist researchers continue to develop higher energy-dense solutions to close the gap with ICEs, it is abundantly clear that the integration strategy for these batteries from cell level to pack level is a critical component in making EVs competitive with gasoline cars. But the system-level design of the battery brings with it a lot of safety concerns with respect to thermal and mechanical operational constraints. Rather than relying on extrapolation from cell-level mechanical and thermal tests, the BILDE lab experiments with mechanical and thermal abuse of modules to fine-tune computational models that are used in multidisciplinary optimization schemes to produce a more efficient design of EV battery packs.